- Home

- Scotland's changing climate

- Urban Housing in Scotland

- Maintenance

- Ventilation

- Airtightness

- Insulation

- Lofts - insulation at ceiling level

- Lofts - insulation at rafter level

- Cavity wall insulation

- Solid Walls: Internal vs External Insulation

- Internal Solid Wall Insulation (IWI)

- External Solid Wall Insulation (EWI)

- Timber frame retrofit

- Windows and doors

- Openings in 'historical' buildings

- Openings in 'non-historical' buildings

- Ground floors

- Suspended floors

- Suspended floors - from below

- Suspended floors - from above

- Solid floors

- Insulation materials

- Building science

- Space heating

- Solar energy

- Product Selector

Insulation Materials

Insulation considerations

- Lambda value indicates how well the material resists heat loss and is important, but not the only consideration.

- Even tiny gaps within or around insulation will allow heat to bypass, so it has to be fitted without any gaps. This is not easy in practice, so the practical difficulties of ensuring snugger components like a timber frame – using materials with the fit between both a little 'give' – is often as important as lambda value.

- Because it is hard in practice to avoid gaps, it's worth trying to add air barriers (but not moisture barriers) on either side of – and tight up against the insulation. These prevent air from entering, so gaps within the insulation are less of a problem. With rigid boards, taping all joints will have a similar benefit.

- Cold air can flow across and through the outside face using mineral wools or sheep's wool fibrous insulation. Although not penetrating to the inside, this 'wind-washing' can wick heat away and, where possible, should be prevented through a membrane.

- There are several health concerns about some synthetic insulation materials. These are controversial, but SEDA has always sought to use the precautionary principle in such matters, and where possible (affordable), we suggest using natural materials.

- Natural insulation materials (sheep wool, wood fibre, flax, hemp, cork, etc.) tend to be 'hygroscopic', which means they can absorb, safely store and desorb moisture. This has several advantages, including protecting adjacent (usually timber) structural elements from excess moisture. They are also 'breathable', meaning moisture can pass through safely and dissipate where designed as part of a 'breathable' system.

- Overall, synthetic insulation materials (mineral wools and plastic foamed products) tend to have high embodied energy (which is worse) relative to the natural insulation options.

- There are some recycling arrangements in place for some synthetic insulation materials, but it is only sometimes economical to undertake. Natural insulations are usually biodegradable or compostable and so represent a zero-waste option.

- Insulation needs to be installed in a wide variety of situations, and some of these have quite specific requirements, for example, related to fire (high-rise buildings), high compression resistance (under the ground floor slab), acoustics (between properties) or vapour resistance (around water pipes). These requirements outweigh any of the considerations above.

- There are many commonly used insulation products, such as boards, rolls and batts, and most of our guidance relates to these. However, there are also some less common ones, such as insulating plaster, loose fill granules, fibres or beads and sprayed-on foams, and although not necessarily mentioned, these may be appropriate in some situations. The important thing to consider is the long-term performance as well as any more obvious or immediate advantages.

'Natural' / Organic insulation materials

Organic insulation materials offer a sustainable and renewable alternative to conventional insulation options. However, it's essential to ensure that these materials have been processed and treated to meet safety and performance standards. Check for relevant certifications.

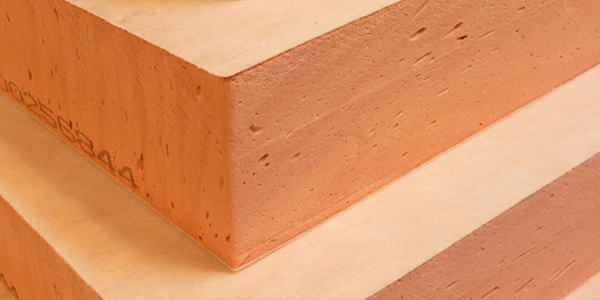

Wood fibre insulation

Wood fibre insulation is made from forestry thinnings and saw mill residue. Polyolefin fibres provide binding, and the fire retardant is usually ammonium phosphate. Wood fibre insulation is used in breathing wall construction, ventilated pitched roofs, ceilings, and floors.

Thermal conductivity/ λ (lambda) W / m . K = 0.038

Cellulose insulation

Cellulose insulation is made from recycled newspaper. The material is usually treated with a mixture of borax and boric acid to provide fire resistance and repel insects and fungi. The insulation is suitable for use between rafters and joists and timber 'breathing' wall construction. Cellulose insulation is available in a loose format for pouring and dry or damp spraying and in slab format for fitting within metal or timber frames.

Thermal conductivity/ λ (lambda) W / m . K = 0.035 in lofts; 0.038 - 0.040 in walls.

Sheep's wool insulation

Sheep’s wool slabs and rolls are made from wool with a polyester binder and treated for fire and insect resistance. Wool is suitable for insulation between rafters, joists and timber studs in timber ‘breathing’ wall construction. Sheep’s wool has excellent hygroscopic properties that help to moderate temperatures throughout the seasons.

Thermal conductivity/ λ (lambda) W / m . K = 0.038

Cork insulation

Cork insulation is made from cork bark harvested from the tree every 25 years. Cork granules are expanded and then formed into blocks, using the natural resin, through high temperature and pressure. The most common applications for cork insulation are in flat roofs and insulated render systems, both of which take advantage of cork’s dimensional stability and resistance to compression.

Thermal conductivity/ λ (lambda) W / m . K = 0.037 - 0.040

Hemp insulation

Hemp insulation is an eco-friendly and sustainable type of insulation material made from the fibres of the hemp plant (Cannabis sativa). It can be installed in walls, roofs, floors, and attics and used in new construction and retrofit projects.

Thermal conductivity/ λ (lambda) W / m . K = 0.039 - 0.040

Mineral insulation materials

Mineral insulation materials, or inorganic insulation materials, are insulating materials derived from minerals and rocks. They have excellent fire resistance and thermal performance. However, their manufacture usually involves significant amounts of energy. Further, some mineral insulation materials may release fine particles that can be harmful when inhaled, so appropriate safety measures should be taken during installation and handling.

Rock mineral wool

Rock mineral wool is made from quarried diabase rock and recycled steel slag. The insulation is produced in various densities according to format and function. Varying densities result in varying levels of thermal conductivity. Applications include masonry cavity walls, timber frame walls, roof rafter insulation, loft and suspended floor insulation.

Thermal conductivity/ λ (lambda) W / m . K = 0.032–0.044

Glass mineral wool

Glass wool insulation is manufactured in a similar way to rock wool. However, the raw materials and the melting process are different. Glass wool is made from silica sand, recycled glass, limestone and soda ash. The insulation is produced in various densities according to format and function. Varying densities result in varying levels of thermal conductivity. Applications include masonry cavity walls, timber frame walls, roof rafter insulation, loft and suspended floor insulation.

Thermal conductivity/ λ (lambda) W / m . K = 0.035

Aerogel insulation

Aerogel is a lightweight, low-density material made from silica and air. Relatively new on the market, aerogel blankets are beginning to appear as a component in laminate panels bonded to boards, including plasterboard, wood fibre-reinforced gypsum board, plywood, and chipboard. The panels are distinguished by their outstanding insulation properties—generally an expensive option.

Thermal conductivity/ λ (lambda) W / m . K = 0.014

Cellular or foamed glass insulation

Not very common in retrofit, foamed glass insulation is made from crushed glass mixed with carbon and heated to 1000ºC. The heat causes the carbon to oxidise to form the characteristic bubbles. Foamed glass has a relatively high compressive strength, which, combined with its water and vapour resistance, makes the insulation slab suitable for flat roofing in high-load situations such as retaining walls, car parks and green roofs. Other applications include thermal breaks, wall, and floor insulation.

Thermal conductivity/ λ (lambda) W / m . K = 0.041

Oil - based polymer insulation materials

Oil-based polymer insulation materials are synthetic insulation derived from petrochemical sources. These materials are made from polymers derived from crude oil or natural gas. They are widely used in the construction industry. As polymers derived from fossil fuels, though highly effective, they are subject to resource depletion and, therefore, inherently unsustainable.

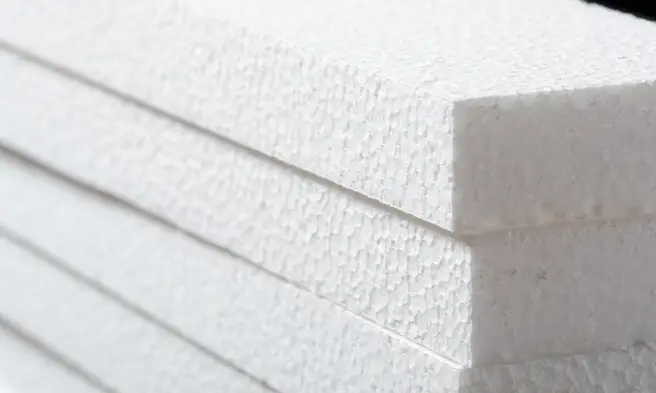

Expanded Polystyrene (EPS) insulation

Expanded Polystyrene insulation is made from tiny beads of polystyrene mixed with pentane as the blowing agent. Heating expands the beads. EPS boards are produced by putting the beads into moulds and heating them further to fuse the beads together. Typical applications of EPS boarding are in walls, roofs and floors. Polystyrene beads are frequently used as cavity fill in masonry walls.

Expanded polystyrene's physical properties make it a pernicious pollutant. Its lightweight composition and buoyancy allow EPS to float easily and travel considerable distances – via rivers into the oceans. Research shows that 80% of all ocean pollution originates from the land, of which EPS is a significant component.

Thermal conductivity/ λ (lambda) W / m . K = 0.034–0.038

Extruded Polystyrene (XPS) insulation

Extruded Polystyrene (XPS) is made by mixing polystyrene with a blowing agent under pressure, forcing the resulting fluid through a die. As it emerges from the die, it expands into a foam-shaped, cooled and trimmed to dimension. XPS is slightly stronger than EPS, and although it is used in many of the same applications as EPS, it is particularly suitable for use below ground or where extra loading and impacts might be anticipated.

Thermal conductivity/ λ (lambda) W / m . K = 0.033–0.035

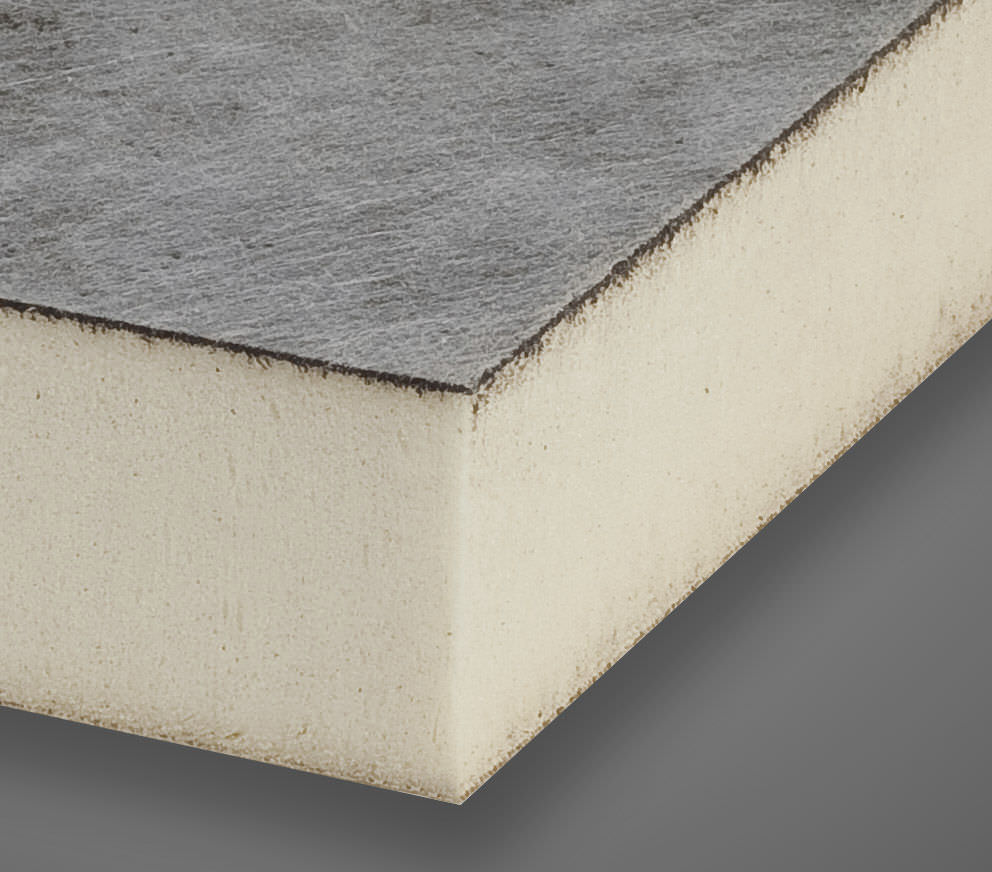

Rigid polyurethane (PUR/PIR) insulation

Polyurethane (PUR), a closed-cell plastic, is formed by reacting two monomers in the presence of a blowing agent catalyst (polymerisation). Polyisocyanurate foam (PIR) improves polyurethane with a slight difference in the constituents, and the reaction is conducted at higher temperatures. PIR is more fire-resistant and has a slightly higher R-value. Applications include wall, floor and roof insulation. Polyurethane is also popular as an insulation backing to rigid boarding such as plasterboard.

Thermal conductivity/ λ (lambda) W / m . K = 0.023–0.026

Phenolic foam insulation

Phenolic foam insulation is made by combining phenol-formaldehyde resin with a foaming agent. When hardener is added to the mix and rapidly stirred, the exothermic reaction of the resin, together with the foaming agent's action, causes the resin's foaming. This is followed by rapid setting of the foamed material. Though more usually employed in building services applications, phenolic foam panels are suitable as insulation for roofs, walls and floors. Phenolic foam is also popular in laminate form as an insulation backing to rigid boarding such as plasterboard.

Thermal conductivity/ λ (lambda) W / m . K = 0.020